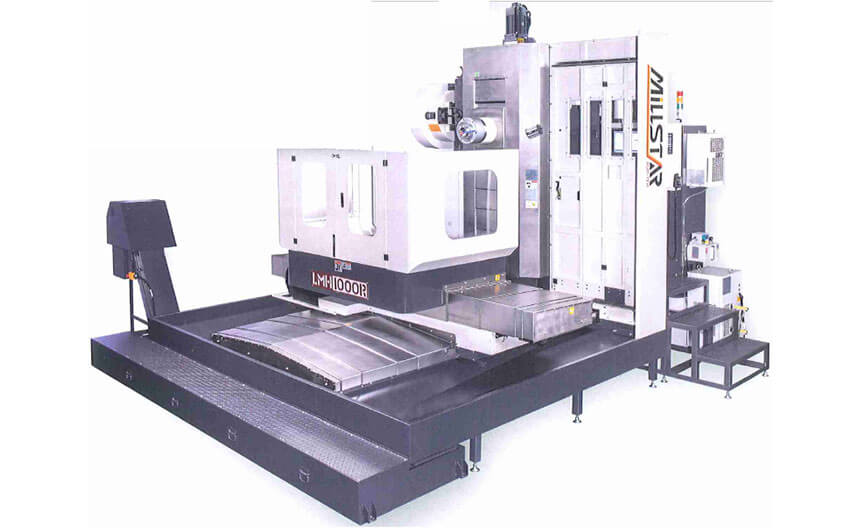

LMH1000

- The major structural parts are ladle and box type integrated construction to fully overcome the cutting “Blind Rigidity” problem.

- Three axes are mounted with heavy duty roller type linear guide ways, featuring heavy load resistance and rapid traverse.

- High precision rotary table with 0.001o(LMH std.) indexing makes machining more smoothing.

- Coolant through ball screws on 3 axes ensures long term machining accuracy and extends the service life of the ball screw.(LMH std.)

- The advanced finite element analysis software is applied for simulating structural stress. This assures the best possible machine rigidity, stability and dampening capacity. rotary table with 0.001o

| Model | LMH1000R |

|---|---|

| Work Table | 1000 X 1250 mm(0.001o分割) |

| T-slot | 22 X P100 X 9 |

| Max. Loading | 2000kg |

| X/Y/Z 3 axes travel | 1530 X 1250 X 1250mm |

| Spindle nose to work table center | 230~1280mm |

| Spindle center to work table surface | 50~1300mm |

| Method of spindle | Gear Head(Hi-Low 2 speed) |

| Spindle Taper | BT50 |

| Spindle Diameter | 100 mm |

| Spindle Speed | 6000 rpm (Gear head - high and low gear) |

| X/Y/Z 3 axes Slide Way | 3 Axis Roller Type Linear Way |

| X/Y/Z 3 axes Cutting Feed rate | 15/15/12 m/min |

| X/Y/Z 3 axes Rapid Feed rate | 6 m/min |

| ATC | 鏈條式 |

| Tool Selection | CHAIN Type |

| Max. Tool Diameter X Length | Φ125 X 400 mm |

| Max. Tool Weight | 15KG |

| Tool Shank | BT-50 |

| Tool magazine capacity | 40T |

| Spindle Motor(con./30 min.) | 15/18.5 KW |

| X/Y/Z axis motor | 7/6/7/7 KW |

| X/Y/Z axis Ball Screw | X/Z:Φ50 X P10,Y:Φ63 XP12 |

| Coolant tank capacity | 660W |

| External Dimension(L X W X H)(Approx) | 6218 X 5646 X 3957 mm |

| Net Weight/ Gross weight (Approx) | 19000kg/21500kg |

| Splash Guard | Half splash cover |

| Coolant Tank Capacity | 40”FR+40”HQ |

| Shipment Require | 1000L |

| Standard Accessories: | Optional Accessories: |

| 1. FANUC Oi MF controller+8.4”LCD | 1. M800/Fanuc-31iMB/Heidenhain/Siemens |

| 2. Gear Head Spindle | 2. 10.4” LCD display |

| 3. Spindle speed 6,000 rpm, Gear Head | 3. CTS 20/50/70 BAR |

| 4. Spindle oil cooler | 4. ATC:Chain type 60T |

| 5. Spindle curtain coolant | 5. Direct drive spindle 8,000/10,000 rpm(BT50) |

| 6. Coolant system | 6. 3 axis linear scale |

| 7. Auto power off | 7. Work piece and tool length measuring device |

| 8. Heat exchanger for electric cabinet | 8. Air conditioner for electric cabinet |

| 9. Auto lubrication system | 9. Full splash cover |

| 10. ATC: 40T chain typ | 10. 4th axis preparation |

| 11. Rigid tapping | 11. 5th axis preparation |

| 12. Half cover | 12. CE Standard |

| 13. M code air blasting | 13. Chain type chip conveyor with cart |

| 14. Oil skimmer | 14. 4th axis rotary table(LMH std.) |

| 15. Double screw type chip conveyor with cart | |

| 16. Quartz working light | |

| 17. Tool box with tools | |

| 18. Transformer(Export only) |