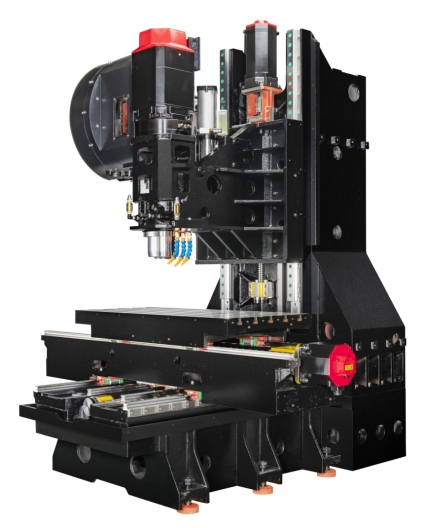

LMV 1000P

- Machine is Made of Meehanite Casting with internal ribs running throughout each section, featuring long term metallic rigidity and stability.

- High precision ball screws (C3 class) on 3 axes are pre-loaded to eliminate thermal displacement. The ball screws are modularly assembled, the parallemlism and squareness accuracy are calibrated within 0.01mm, in full length.

- Linear type use precision Roller type linear way (LV1400-2000).

- ATC arm type 24 tools (std.) for 80-1600.

| Model | LMV1000P | ||

|---|---|---|---|

| Table | Work Table | 1200 X 550 mm | |

| T-slot | 100 X 18 mm X 5T | ||

| Max. loading | 1000 kg | ||

| Travel | Three Axes Travel | 1000 X 600 X 620 mm | |

| Spindle Nose To Table Surface | 130~750mm | ||

| Spindle center to Column side Ways | 646 mm | ||

| Spindle | Spindel Taper | BT40 | |

| Spindel Diameter(ID) | Φ70 mm | ||

| Spindel Speed | 10000 rpm | ||

| Feedrate | 3 Axes Slide Ways | Linear Way | |

| 3 Axes Rapid Feedrate | 36,36:24 m/min | ||

| 3 Axes Cutting Feedrate | 12/12/12 m/min | ||

| ATC | Tool Magazine type | Arm type | |

| Tool Selection | Bi-direction shortest path | ||

| Max. Tool Weight | 7 kg |

|

|

| Max. Tool Diameter x Length | Φ75 X 250 mm | ||

| ATC Capcity | 24T | ||

| Motor | Spindle Motor | 7.5/11 kw | |

| X,Y,Z axis Servomotor | 3/3/7 kw | ||

| Coolant Pump | 850W | ||

| Miscellaneous | External Dimensions (L x W x H) | 2800 X 2360 X 2780 mm | |

| N.W/G.W (apprax.) | 6700/7400 kg | ||

| Coolant Tank Capacity | 420L | ||

| Standard Accessories: | Optional Accessories: |

| 1. Mitbushi M80 controller | 1. Fanuc/Mitsubishi/Siemens/Heidenhain Controller |

| 2. 10.4” color LCD | 2. 15” color LCD |

| 3. Leveling kits and blocks | 3. Direct drive spindle 12,000-15,000 rpm (BT-40) |

| 4. Tool box | 4. Direct drive spindle 8,000-10,000 rpm(BT-50) |

| 5. Spindle air blow system | 5. 4th axis preparation (not include motor & drive) |

| 6. Coolant System | 6. CNC rotary table |

| 7. Spindle oil cooler | 7. Coolant through spindle 20/30/50/70 BAR |

| 8. Auto power off | 8. Air condition in electrical cabinet |

| 9. Heat exchanger | 9. 32 tools chain type ATC |

| 10. Auto lucrication system | 10. Steelbelt / Scraper type chip conveyor |

| 11. 24 tools Arm type tool changer | 11. High pressure chip flushing system |

| 12. Rigid tapping | 12. CE norm |

| 13. Screw type chip conveyor and cart | 13. Oil skimmer |

| 14. M code air blasting | 14. Tools measurement |

| 15. CF / USB interface / RJ45 | 15. Workpiece measurement |

| 16. Full splash guard | 16. 3 axes Linear scale |

| 17. Working light | |

| 18. Spindle curtain coolant |